By Gordon Larsen, Senior Technical Instructor, NGVi

CNG fuel systems, especially for heavy-duty natural gas vehicles, have evolved greatly over the past decade. In today’s heavy-duty trucks and buses, CNG storage cylinders are combined into modules and installed on vehicles as a unit. The systems are engineered and installed according to NFPA 52, the installation code. One advantage of the modular concept is a clean, neat design that is easier to install.

Both engineering and installation of CNG fuel systems affect the ability of inspectors to perform required inspections. That’s why CNG fuel system inspectors must be thoroughly familiar with NFPA 52, the installation code for CNG fuel systems. Designed to ensure safety, NFPA 52 dictates everything from minimum clearances to proper installation locations to the design and construction of CNG cylinder packages, and is the guiding document not only for the initial installation of CNG fuel system components, but also for inspection. Besides assessing any damage or disrepair, it is the CNG fuel system inspector’s job to ensure that each component of the system is installed according to code.

Component Access is the Key

The most common cylinder configuration for heavy-duty trucks is back-of-cab and/or saddle mounted cylinders. Back-of-cab cylinders are installed inside a protective cabinet which may or may not have inspection access panels. Older models of heavy-duty trucks may not have access panels or, if they do, the panels don’t provide adequate access. It is generally accepted that cabinets and shields do not have to be completely removed unless there is no other way to visualize the entire surface of every cylinder.

Saddle mounted cylinders are located on the side of the truck and also feature a protective shield that may be combined into a single module with the fuel management module. Inspection of these cylinders may not be possible without removing the entire shield. The ease with which shields can be removed varies from vehicle to vehicle.

So What Are the Challenges?

A long-standing myth in the industry is that no visible damage to the shields automatically means there is no damage to cylinders. That is not the case. More frequently than not, when we deliver CNG fuel system inspector training, we see shields that are installed too close to cylinders, where the shields themselves rub on the cylinders and cause damage. This is because the minimum clearance was not obtained during installation, or even may have been altered during an accident.

Also, because of the challenges associated with visualizing 360 degrees around every CNG cylinder on some vehicles, some inspectors just don’t perform the complete inspection because of the time required to remove shields when necessary. While it saves time, this practice puts the company that owns the vehicle and/or that performs the inspection at huge risk in the event of an incident.

Improper drainage is another challenge that can cause unnecessary cylinder damage. NFPA 52 requires that the shields be able to drain solids and liquids away from cylinders. This usually means that holes are drilled at appropriate intervals. At a recent class for a large freight delivery customer of NGVi, it was discovered that there was no allowance for drainage provided with the original CNG fuel system installation.

Another frequently encountered challenge is improper protection from exhaust and other heat-producing components. NFPA 52 2013 and prior versions require that any cylinder within eight inches of exhaust must be insulated or protected from heat in another acceptable manner. We also frequently encounter fuel systems where other components like hydraulic pumps have created damage.

Large-Diameter Cylinders Present Special Challenges

Development of large diameter cylinders has allowed NGV manufacturers to produce vehicles that feature range comparable to diesel vehicles. However, large diameter belly-mounted cylinders present special challenges that CNG fuel system inspectors must be aware of.

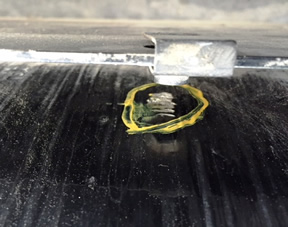

However, because of their size, the amount of expansion and contraction with large-diameter cylinders is greater, which in turn creates greater and more frequent problems with mounting brackets and gaskets. CNG fuel system inspectors must be able to identify and diagnose the common problems associated with these components: overtightened brackets that cause gaskets to split or be cut or “squeeze out” from under the brackets and allow brackets to damage cylinders.

The use of neck-mounted CNG cylinders helps mitigate this challenge, but

belly-mounted cylinders are still very prevalent in existing vehicles and will continue to need attention.

Meeting the Challenges

Several actions can help CNG fuel system inspectors meet the CNG fuel system inspection challenges identified in this article.

- A pre-in-service (detailed visual) inspection of every vehicle is essential. This allows technicians to establish a baseline condition for every new vehicle before it is placed into service and to detect any problems (like inadequate bolt clearances) BEFORE the problems become severe.

- Every CNG fuel system inspector must be thoroughly trained on NFPA 52 installation requirements for CNG fuel systems, in addition to how to identify and assess damaged components, including cylinders. The time invested in this training does not compare to the risk a company would take by not adequately preparing its technicians to perform the inspections.

- Establish a policy that EVERY CNGcylinder must be inspected and ensure technicians have the right tools to inspect cylinders that are located in tight spaces. These include a flashlight, a long-handled inspection mirror and a camera with an extension device. (At NGVi, we use a Go-Pro camera withan extension rod.)

- Make sure EVERY vehicle that is involved in an accident—no matter how minor it seems—receives a detailed CNG fuel system inspection. Impact of even five miles per hour can have an adverse impact on CNG fuel systems.

Today’s CNG vehicles are a great improvement over those available a decade ago, thanks not only to engine technology development but also to advances in CNG fuel system engineering and installation. Handling challenges with CNG fuel system inspections is yet another way fleets and dealerships can help extend that improvement and ensure that customers have a safe and reliable experience with NGVs.

To learn more about challenges with CNG fuel system inspections, check out NGVi’s

ASE Accredited CNG Fuel System Inspector Training and our CNG Fuel System Inspector Certification Program.